Building sustainable houses within a few days to donate them to families affected by the floods: challenge met by Etex

- It only takes an average of fourteen days to build a house in the factory

- These houses built in a circular way provide an eco-friendly alternative, and reduce waste and energy expenditure by 85%

- The streamlined construction process ensures a very high level of quality for each home

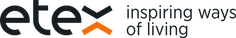

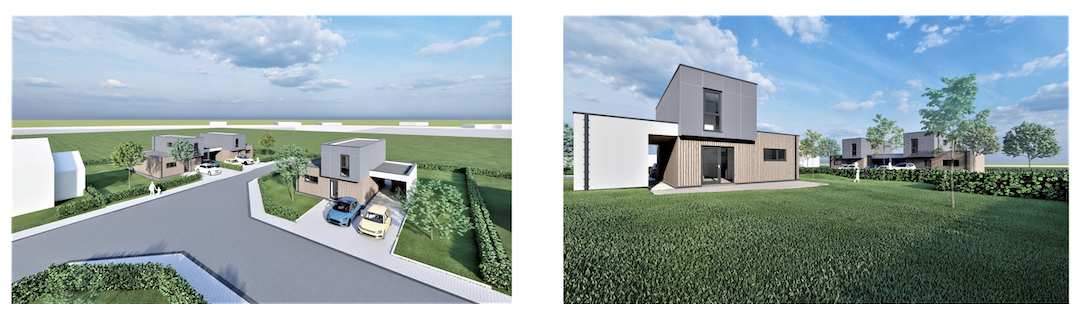

To help several families affected by last summer’s floods in Belgium, five high-quality, sustainable houses built in two weeks are being donated by the Belgian company Etex. Installed in Rochefort and Pepinster, this new type of modular construction is expected to expand in the future to meet needs and new trends in the housing sector. Walloon Minister for Housing Christophe Collignon welcomes this approach.

Etex, a Belgian company based in Zaventem and a worldwide pioneer in lightweight construction, is making available its expertise in modular buildings following the floods of July 2021. Through its e-Loft brand, it has just announced that it will construct three wood-frame houses free of charge in the municipality of Rochefort (province of Namur) in the coming weeks as well as two new homes in Pepinster (province of Liège) within the next months. The three homes in Rochefort are three-bedroom family houses measuring approximately 85m², comprising a ground floor and first floor.

One of Etex’s strategic pillars is to promote sustainability in the way the company operates. That is why the organisation is a leader in lightweight materials and prefabricated construction. These methods offer advantages such as reduced raw material use, energy consumption, waste and emissions. Even more, they contribute to enhanced long-term circularity by creating opportunities for deconstruction, reuse and recycling.

Etex’s e-Loft houses combine thermal performance with respect for the environment. As they are constructed in the factory, almost all the waste is recycled directly there. In addition, the fast and simple construction massively cuts down on the noise or visual pollution of the construction sites thanks to the minimal use of lorries or machinery. This approach reduces waste and energy expenditure by 85% compared with other conventional types of construction.

These homes can be built in two weeks on average, at the same time as guaranteeing high quality, thanks to several crucial innovations. The components of each house are assembled on production lines in the factory to form three-dimensional modules ready to be delivered, which guarantees controlled manufacturing times. The houses are then transported by lorry to the site, where they are assembled in less than 48 hours.

Etex took the initiative to donate five such houses to the municipalities of Rochefort and Pepinster, for which permits have just been confirmed. When this donation was announced, Christophe Collignon, Walloon Minister for Housing, Local Authorities and the City, stated: “I want to applaud here companies like Etex who are committed to Belgian citizens. The Walloon Government has deployed a maximum of measures to allow the rehousing of households and continues to work hard in this direction. In this context, the supply of quality modular housing that is readily available is an important plus, complementing the various systems put in place.”

Bernard Delvaux, CEO of Etex: “At Etex, social responsibility is in our DNA. It was important for us to donate our expertise through these five houses built in a circular way with a very low carbon footprint. Our modular construction technologies meet multiple housing needs around the world with the fast construction of affordable, well-insulated, high-quality and attractive living spaces.”

Assets: